|

Natural Gas

Natural gas, in itself, might be considered an uninteresting gas - it is

colorless, shapeless, and odorless in its pure form.

Natural gas is the gas

component of coal and oil formation. It is used in industrial and

commercial heating and cooking, and, increasingly, to fuel electricity

generation. In a compressed form, natural gas can also be used as a

transportation fuel. Natural gas is either found mixed in oil or is

released from coal. Energy in 6,000 cubic feet of natural gas is

equivalent to one barrel of oil.

Wells for natural gas

are drilled in underground reservoirs of porous rock. When it is

removed from a reservoir, natural gas can either be pumped to the

processing station for removal of liquid hydrocarbons, sulfur,

carbon dioxide, and other components, or stored in large caverns

underground until it is needed. Pipelines are the main method of

transporting natural gas. Natural gas can also be liquefied and

shipped overseas, but this process is complex and expensive.

Electrical generation

by natural gas has been improved by the development of

combined-cycle systems. These systems put together a

natural-gas-fueled combustion turbine with a heat-recovery steam

generator and steam turbine, to produce electricity in two ways

rather than just one. The result: roughly 60 percent of the heat

from the natural gas is harnessed to make electricity, creating a

more energy-efficient system.

Natural gas was formed millions of

years ago when most of the earth was covered by water. Plant and tiny animal

remains were mixed and layered with sand and mud. When the Earth underwent

natural but drastic changes to form today’s landscape, the intense heat and

pressure transformed these fossils into hydrocarbons—chemical compounds of

hydrogen and carbon atoms. Natural gas is made up mainly of a chemical called

methane, a simple, compound that has a carbon atom surrounded by four hydrogen

atoms. Methane is highly flammable and burns almost completely. There is no ash

and very little air pollution. Depending on the arrangement of the atoms, what

were once sea plants and animals are now natural gas or crude oil deposits

contained in the earth’s crust. Natural gas (a combustible, gaseous mixture of

simple hydrocarbons) is a very light portion of petroleum, which includes both

natural gas and crude oil. Natural gas may rise to the surface through natural

openings in the earth’s crust or can be brought to the surface through man-made

wells. Humans discovered thousands of years ago that this naturally occurring

resource could be burned and used for heat and light.

|

|

|

Natural gas is nothing

new. In fact, most of the natural gas that is brought out

from under the ground is millions and millions of years old.

However, it was not until recently that methods for

obtaining this gas, bringing it to the surface, and putting

it to use were developed.

Before there was an

understanding of what natural gas was, it posed somewhat of

a mystery to man. Sometimes, such things as lightning

strikes would ignite natural gas that was escaping from

under the earth's crust. This would create a fire coming

from the earth, burning the natural gas as it seeped out

from underground. These fires puzzled most early

civilizations, and were the root of much myth and

superstition. One of the most famous of these types of

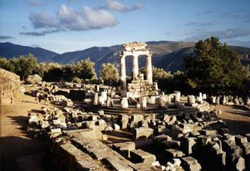

flames was found in ancient Greece, on Mount Parnassus

approximately 1000 B.C. A goat herdsman came across what

looked like a 'burning spring', a flame rising from a

fissure in the rock. The Greeks, believing it to be of

divine origin, built a temple on the flame. This temple

housed a priestess who was known as the Oracle of Delphi,

giving out prophecies she claimed were inspired by the

flame.

|

|

The Oracle at Delphi, Greece |

|

Source: Pascal Troxler |

These types of springs

became prominent in the religions of India, Greece, and

Persia. Unable to explain where these fires came from, they

were often regarded as divine, or supernatural. It wasn't

until about 500 B.C. that the Chinese discovered the

potential to use these fires to their advantage. Finding

places where gas was seeping to the surface, the Chinese

formed crude pipelines out of bamboo shoots to transport the

gas, where it was used to boil sea water, separating the

salt and making it drinkable.

Britain was the first

country to commercialize the use of natural gas. Around

1785, natural gas produced from coal was used to light

houses, as well as streetlights.

|

|

A Natural Gas Streetlight |

|

Source: DOE |

Manufactured natural

gas of this type (as opposed to naturally occurring gas) was

first brought to the United States in 1816, when it was used

to light the streets of Baltimore, Maryland. However, this

manufactured gas was much less efficient, and less

environmentally friendly, than modern natural gas that comes

from underground.

Naturally occurring

natural gas was discovered and identified in America as

early as 1626, when French explorers discovered natives

igniting gases that were seeping into and around Lake Erie.

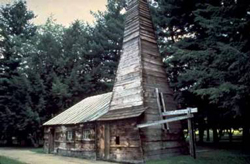

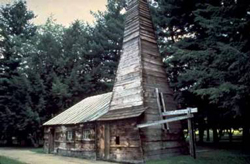

The American natural gas industry got its beginnings in this

area. In 1859, Colonel Edwin Drake (a former railroad

conductor who adopted the title 'Colonel' to impress the

townspeople) dug the first well. Drake hit oil and natural

gas at 69 feet below the surface of the earth.

|

|

A Reconstruction of 'Colonel' Drake's First Well in

Titusville, Pa |

|

Source: API |

Most in the industry

characterize this well as the beginning of the natural gas

industry in America. A two-inch diameter pipeline was built,

running 5 and ½ miles from the well to the village of

Titusville, Pennsylvania. The construction of this pipeline

proved that natural gas could be brought safely and

relatively easily from its underground source to be used for

practical purposes.

In 1821, the first

well specifically intended to obtain natural gas was dug in

Fredonia, New York by William Hart. After noticing gas

bubbles rising to the surface of a creek, Hart dug a 27-foot

well to try and obtain a larger flow of gas to the surface.

Hart is regarded by many as the 'father of natural gas' in

America. Expanding on Hart's work, the Fredonia Gas Light

Company was eventually formed, becoming being the first

American natural gas company.

During most of the

19th century, natural gas was used almost exclusively as a

source of light. Without a pipeline infrastructure, it was

difficult to transport the gas very far, or into homes to be

used for heating or cooking. Most of the natural gas

produced in this era was manufactured from coal, as opposed

to transported from a well. Near the end of the 19th

century, with the rise of electricity, natural gas lights

were converted to electric lights. This led producers of

natural gas to look for new uses for their product.

In 1885, Robert Bunsen

invented what is now known as the Bunsen burner. He managed

to create a device that mixed natural gas with air in the

right proportions, creating a flame that could be safely

used for cooking and heating. The invention of the Bunsen

burner opened up new opportunities for the use of natural

gas in America, and throughout the world. The invention of

temperature-regulating thermostatic devices allowed for

better use of the heating potential of natural gas, allowing

the temperature of the flame to be adjusted and monitored.

|

|

A Typical Bunsen Burner |

|

Source: DOE |

Without any way to

transport it effectively, natural gas discovered pre-WWII

was usually just allowed to vent into the atmosphere, or

burnt, when found alongside coal and oil, or simply left in

the ground when found alone.

One of the first

lengthy pipelines was constructed in 1891. This pipeline was

120 miles long, and carried natural gas from wells in

central Indiana to the city of Chicago. However, this early

pipeline was very rudimentary, and was not very efficient at

transporting natural gas. It wasn't until the 1920s that any

significant effort was put into building a pipeline

infrastructure. After World War II, welding techniques, pipe

rolling, and metallurgical advances allowed for the

construction of reliable pipelines. This post-war pipeline

construction boom lasted well into the ‘60s, and allowed for

the construction of thousands of miles of pipeline in

America.

Once the

transportation of natural gas was possible, new uses for

natural gas were discovered. These included using natural

gas to heat homes and operate appliances such as water

heaters and oven ranges. Industry began to use natural gas

in manufacturing and processing plants. Also, natural gas

was used to heat boilers used to generate electricity. The

transportation infrastructure had made natural gas easy to

obtain, and it was becoming an increasingly popular form of

energy.

|

|

What is Natural Gas?

In its natural state you can’t see

or smell natural gas. It is colorless, odorless and lighter than air.

Mercaptan, a chemical odorant, is added to natural gas so it can be smelled if

it leaks.

Natural gas is made up mostly of

methane, which has a simple hydrocarbon structure of one carbon atom and four

hydrogen atoms (CH4). This means it burns easily and emits less pollution. When

natural gas is burned, it produces mostly carbon dioxide and water vapor. While

natural gas is formed primarily of methane, it can also include ethane,

propane, butane and pentane.

Natural gas can be found in a

variety of different underground formations, including: shale formations,

sandstone beds, coal seams, and deep, salt water aquifers (underground ponds of

water).

Natural gas wells have

traditionally been drilled vertically, at depths ranging from a few thousand

feet to as deep as five miles.

Natural gas can be found in

a variety of different underground formations, including:

-

shale formations

-

sandstone beds

-

coal seams

The Formation of

Natural Gas

Natural gas is a fossil

fuel. Like oil and coal, this means that it is, essentially, the remains

of plants and animals and microorganisms that lived millions and millions

of years ago. But how do these once living organisms become an inanimate

mixture of gases?

There are many different

theories as to the origins of fossil fuels. The most widely accepted

theory says that fossil fuels are formed when organic matter (such as the

remains of a plant or animal) is compressed under the earth, at very high

pressure for a very long time. This is referred to as thermogenic methane.

Similar to the formation of oil, thermogenic methane is formed from

organic particles that are covered in mud and other sediment. Over time,

more and more sediment and mud and other debris are piled on top of the

organic matter. This sediment and debris puts a great deal of pressure on

the organic matter, which compresses it. This compression, combined with

high temperatures found deep underneath the earth, breaks down the carbon

bonds in the organic matter. As one gets deeper and deeper under the

earth’s crust, the temperature gets higher and higher. At low temperatures

(shallower deposits), more oil is produced relative to natural gas. At

higher temperatures, however, more natural gas is created, as opposed to

oil. That is why natural gas is usually associated with oil in deposits

that are 1 to 2 miles below the earth's crust. Deeper deposits, very far

underground, usually contain primarily natural gas, and in many cases,

pure methane.

Natural gas can also be

formed through the transformation of organic matter by tiny

microorganisms. This type of methane is referred to as biogenic methane.

Methanogens, tiny methane-producing microorganisms, chemically break down

organic matter to produce methane. These microorganisms are commonly found

in areas near the surface of the earth that are void of oxygen. These

microorganisms also live in the intestines of most animals, including

humans. Formation of methane in this manner usually takes place close to

the surface of the earth, and the methane produced is usually lost into

the atmosphere. In certain circumstances, however, this methane can be

trapped underground, recoverable as natural gas. An example of biogenic

methane is landfill gas. Waste-containing landfills produce a relatively

large amount of natural gas from the decomposition of the waste materials

that they contain. New technologies are allowing this gas to be harvested

and used to add to the supply of natural gas.

A third way in which

methane (and natural gas) may be formed is through abiogenic processes.

Extremely deep under the earth's crust, there exist hydrogen-rich gases

and carbon molecules. As these gases gradually rise towards the surface of

the earth, they may interact with minerals that also exist underground, in

the absence of oxygen. This interaction may result in a reaction, forming

elements and compounds that are found in the atmosphere (including

nitrogen, oxygen, carbon dioxide, argon, and water). If these gases are

under very high pressure as they move toward the surface of the earth,

they are likely to form methane deposits, similar to thermogenic methane.

Exploration

The practice of locating

natural gas and petroleum deposits has been transformed dramatically in

the last 20 years with the advent of extremely advanced, ingenious

technology. In the early days of the industry, the only way of locating

underground petroleum and natural gas deposits was to search for surface

evidence of these underground formations. Those searching for natural gas

deposits were forced to scour the earth, looking for seepages of oil or

gas emitted from underground before they had any clue that there were

deposits underneath. However, because such a low proportion of petroleum

and natural gas deposits actually seep to the surface, this made for a

very inefficient and difficult exploration process. As the demand for

fossil fuel energy has increased dramatically over the past years, so has

the necessity for more accurate methods of locating these deposits.

Sources of Data

Technology has allowed for

a remarkable increase in the success rate of locating natural gas

reservoirs. In this section, it will be outlined how geologists and

geophysicists use technology and knowledge of the properties of

underground natural gas deposits to gather data that can later be

interpreted and used to make educated guesses as to where natural gas

deposits exist. However, it must be remembered that the process of

exploring for natural gas and petroleum deposits is characteristically an

uncertain one, due to the complexity of searching for something that is

often thousands of feet below ground.

Geological Surveys

Exploration for natural gas

typically begins with geologists examining the surface structure of the

earth, and determining areas where it is geologically likely that

petroleum or gas deposits might exist. It was discovered in the mid 1800s

that ‘anticlinal slopes’ had a particularly increased chance of containing

petroleum or gas deposits. These anticlinal slopes are areas where the

earth has folded up on itself, forming the dome shape that is

characteristic of a great number of reservoirs. By surveying and mapping

the surface and sub-surface characteristics of a certain area, the

geologist can extrapolate which areas are most likely to contain a

petroleum or natural gas reservoir. The geologist has many tools at his

disposal to do so, from the outcroppings of rocks on the surface or in

valleys and gorges, to the geologic information attained from the rock

cuttings and samples obtained from the digging of irrigation ditches,

water wells, and other oil and gas wells. This information is all combined

to allow the geologist to make inferences as to the fluid content,

porosity, permeability, age, and formation sequence of the rocks

underneath the surface of a particular area. For example, in the picture

shown, a geologist may study the outcroppings of rock to gain insight into

the geology of the subsurface areas.

|

|

Surface Geology |

|

Source: Anadarko Petroleum Corporation |

Once the geologist has

determined an area where it is geologically possible for a natural gas or

petroleum formation to exist, further tests can be performed to gain more

detailed data about the potential reservoir area. These tests allow for

the more accurate mapping of underground formations, most notably those

formations that are commonly associated with natural gas and petroleum

reservoirs. These tests are commonly performed by a geophysicist, one who

uses technology to find and map underground rock formations.

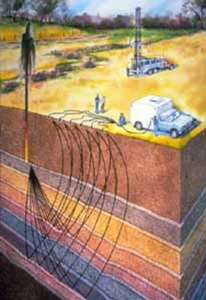

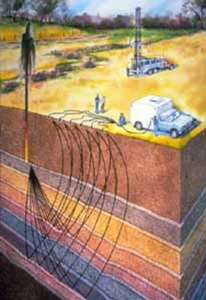

Seismic Exploration

Arguably the biggest

breakthrough in petroleum and natural gas exploration came through the use

of basic seismology. Seismology refers to the study of how energy, in the

form of seismic waves, moves through the Earth's crust and interacts

differently with various types of underground formations. In 1855, L.

Palmiere developed the first 'seismograph', an instrument used to detect

and record earthquakes. This device was able to pick up and record the

vibrations of the earth that occur during an earthquake. However, it

wasn't until 1921 that this technology was applied to the petroleum

industry and used to help locate underground fossil fuel formations.

|

|

Placing Geophones |

|

Source: API |

The basic concept of

seismology is quite simple. As the Earth's crust is composed of different

layers, each with its own properties, energy (in the form of seismic

waves) traveling underground interacts differently with each of these

layers. These seismic waves, emitted from a source, will travel through

the earth, but also be reflected back toward the source by the different

underground layers. Through seismology, geophysicists are able to

artificially create vibrations on the surface and record how these

vibrations are reflected back to the surface, revealing the properties of

the geology beneath.

An analogy that makes

intuitive sense is that of bouncing a rubber ball. A rubber ball that is

dropped on concrete will bounce in a much different way than a rubber ball

dropped on sand. In the same manner, seismic waves sent underground will

reflect off dense layers of rock much differently than extremely porous

layers of rock, allowing the geologist to infer from seismic data exactly

what layers exist underground and at what depth. While the actual use of

seismology in practice is quite a bit more complicated and technical, this

basic concept still holds.

|

|

Seismology in Practice |

|

Source: API |

Onshore Seismology

In practice, using

seismology for exploring onshore areas involves artificially creating

seismic waves, the reflection of which are then picked up by sensitive

pieces of equipment called 'geophones' that are embedded in the ground.

The data picked up by these geophones is then transmitted to a seismic

recording truck, which records the data for further interpretation by

geophysicists and petroleum reservoir engineers. The drawing shows the

basic components of a seismic crew. The source of seismic waves (in this

case an underground explosion) creates that reflect off the different

layers of the Earth, to be picked up by geophones on the surface and

relayed to a seismic recording truck to be interpreted and logged.

Although the seismograph was originally developed to measure earthquakes,

it was discovered that much the same sort of vibrations and seismic waves

could be produced artificially and used to map underground geologic

formations. In the early days of seismic exploration, seismic waves were

|

| A

Seismic Vibrator Truck |

|

Source: Natural Resources Canada |

created using dynamite.

These carefully planned, small explosions created the requisite seismic

waves, which were then picked up by the geophones, generating data to be

interpreted by geophysicists, geologists, and petroleum engineers.

Recently, due to environmental

concerns and improved technology, it is often no longer necessary to use

explosive charges to generate the needed seismic waves. Instead, most

seismic crews use non-explosive seismic technology to generate the

required data. This non-explosive technology usually consists of a large

heavy-wheeled or tracked-vehicle carrying special equipment designed to

create a large impact or series of vibrations. These impacts or vibrations

create seismic waves similar to those created by dynamite. In the seismic

truck shown, the large piston in the middle is used to create vibrations

on the surface of the earth, sending seismic waves that are used to

generate useful data.

Offshore Seismology

The same sort of process is

used in offshore seismic exploration. When exploring for natural gas that

may exist thousands of feet below the seabed floor, which may itself be

thousands of feet below sea level, a slightly different method of seismic

exploration is used. Instead of trucks and geophones, a ship is used to

pick up the seismic data and hydrophones are used to pick up seismic waves

underwater. These hydrophones are towed behind the ship in various

configurations depending on the needs of the geophysicist. Instead of

using dynamite or impacts on the seabed floor, the seismic ship uses a

large air gun, which releases bursts of compressed air under the water,

creating seismic waves that can travel through the Earth's crust and

generate the seismic reflections that are necessary.

|

|

Offshore Seismic Exploration |

|

Source: U.S. Geological Survey |

Magnetometers

In addition to using

seismology to gather data concerning the composition of the Earth's crust,

the magnetic properties of underground formations can be measured to

generate geological and geophysical data. This is accomplished through the

use of magnetometers, which are devices that can measure the small

differences in the Earth's magnetic field. In the early days of

magnetometers, the devices were large and bulky, and only able to survey a

small area at a time.

Gravimeters

In addition to using

variances in the Earth's magnetic field, geophysicists can also measure

and record the difference in the Earth's gravitational field to gain a

better understanding of what is underground. Different underground

formations and rock types all have a slightly different effect on the

gravitational field that surrounds the Earth. By measuring these minute

differences with very sensitive equipment, geophysicists are able to

analyze underground formations and develop clearer insight into the types

of formations that may lie below ground, and whether or not the formations

have the potential for containing hydrocarbons like natural gas.

Exploratory Wells

The best way to gain a full

understanding of subsurface geology and the potential for natural gas

deposits to exist in a given area is to drill an exploratory well. This

consists of digging into the Earth's crust to allow geologists to study

the composition of the underground rock layers in detail. In addition to

looking for natural gas and petroleum deposits by drilling an exploratory

well, geologists also examine the drill cuttings and fluids to gain a

better understanding of the geologic features of the area. Logging,

explained below, is another tool used in developed as well as exploratory

wells. Drilling an exploratory well is an expensive, time consuming

effort. Therefore, exploratory wells are only drilled in areas where other

data has indicated a high probability of petroleum formations.

Logging

Logging refers to

performing tests during or after the drilling process to allow geologists

and drill operators to monitor the progress of the well drilling and to

gain a clearer picture of subsurface formations. There are many different

types of logging, in fact; over 100 different logging tests can be

performed, but essentially they consist of a variety of tests that

illuminate the true composition and characteristics of the different

layers of rock that the well passes through. Logging is also essential

during the drilling process. Monitoring logs can ensure that the correct

drilling equipment is used and that drilling is not continued if

unfavorable conditions develop.

It is beyond the scope of

this website to get into detail concerning the various types of logging

tests that can be performed. Various types of tests include standard,

electric, acoustic, radioactivity, density, induction, caliper,

directional and nuclear logging, to name but a few. Two of the most

prolific and often performed tests include standard logging and electric

logging.

Standard logging consists

of examining and recording the physical aspects of a well. For example,

the drill cuttings (pieces of rock displaced by the drilling of the well)

are all examined and recorded, allowing geologists to physically examine

the subsurface rock. Also, core samples are taken by lifting a sample of

underground rock intact to the surface, allowing the various layers of

rock and their thickness to be examined. These cuttings and cores are

often examined using powerful microscopes that can magnify the rock up to

2,000 times. This allows the geologist to examine the porosity and fluid

content of the subsurface rock, and to gain a better understanding of the

earth in which the well is being drilled.

Electric logging consists

of lowering a device used to measure the electric resistance of the rock

layers in the 'down hole' portion of the well. This is done by running an

electric current through the rock formation and measuring the resistance

that it encounters along its way. This gives geologists an idea of the

fluid content and characteristics. A newer version of electric logging,

called induction electric logging, provides much the same types of

readings, but is more easily performed and provides data that is more

easily interpreted.

|

| An

Example of Well Log Data |

|

Source: U.S. Geological Survey |

An example of the data

obtained through various forms of logging is shown below. In this

representation, the different columns indicate the results of different

types of tests. The data is interpreted by an experienced geologist,

geophysicist, or petroleum engineer, who is able to learn from what appear

as 'squiggly' lines on the well data readout.

The drilling of an

exploratory or developing well is the first contact that a geologist or

petroleum engineer has with the actual contents of the subsurface geology.

Logging, in its many forms, uses this opportunity to gain a fuller

understanding of what actually lies beneath the surface. In addition to

providing information specific to that particular well, vast archives of

historical logs exist for geologists interested in the geologic features

of a given or similar area.

Data Interpretation

There are many sources of

data and information for the geologist and geophysicist to use in the

exploration for hydrocarbons. However, this raw data alone would be

useless without careful and methodical interpretation. Much like putting

together a puzzle, the geophysicist uses all of the sources of data

available to create a model, or educated guess, as to the structure of the

layers of rock under the ground. Some techniques, including seismic

exploration, lend themselves well to the construction of a hand- or

computer-generated visual interpretation of an underground formation.

Other sources of data, such as that obtained from core samples or logging,

are taken into account by the geologist when determining the subsurface

geological structures. Despite the amazing evolution of technology and

exploration techniques, the only way of being sure that a petroleum or

natural gas reservoir exists is to drill an exploratory well. Geologists

and geophysicists can make their best guesses as to the location of

reservoirs, but these are not infallible.

2-D Seismic

Interpretation

Two-dimensional seismic

imaging refers to geophysicists using the data collected from seismic

exploration activities to develop a cross-sectional picture of the

underground rock formations. The geophysicist interprets the seismic data

obtained from the field, taking the vibration recordings of the

seismograph and using them to develop a conceptual model of the

composition and thickness of the various layers of rock underground. This

process is normally used to map underground formations, and to make

estimates based on the geologic structures to determine where it is likely

that deposits may exist.

Another technique using

basic seismic data is known as 'direct detection.' In the mid-1970s, it

was discovered that white bands, called 'bright spots', often appeared on

seismic recording strips. These white bands could indicate deposits of

hydrocarbons. The nature of porous rock that contains natural gas could

often result in reflecting stronger seismic reflections than normal,

water-filled rock. Therefore, in these circumstances, the actual natural

gas reservoir could be detected directly from the seismic data. However,

this does not hold universally. Many of these 'bright spots' do not

contain hydrocarbons, and many deposits of hydrocarbons are not indicated

by white strips on the seismic data. Therefore, although adding a new

technique of locating petroleum and natural gas reservoirs, direct

detection is not a completely reliable method.

Computer Assisted

Exploration

One of the greatest

innovations in the history of petroleum exploration is the use of

computers to compile and assemble geologic data into a coherent 'map' of

the underground. Use of this computer technology is referred to as 'CAEX',

which is short for 'computer assisted exploration'.

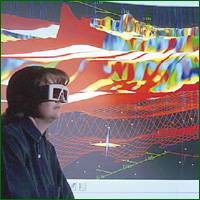

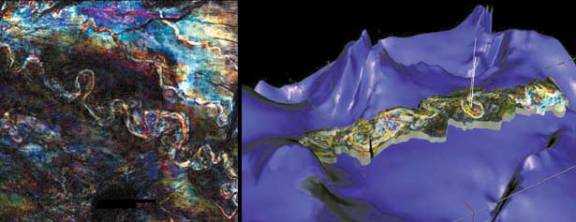

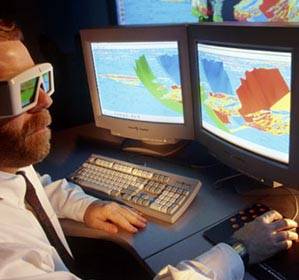

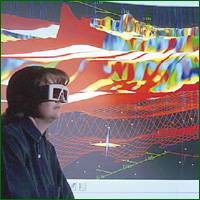

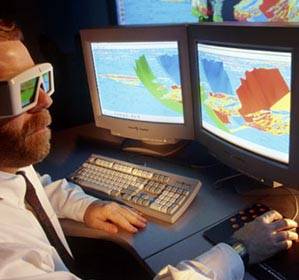

|

Geologist Using Interactive 3-D Seismic

|

|

Source: BP |

With the development of the

microprocessor, it has become relatively easy to use computers to assemble

seismic data that is collected from the field. This allows for the

processing of very large amounts of data, increasing the reliability and

informational content of the seismic model. There are three main types of

computer-assisted exploration models: two-dimensional (2-D),

three-dimensional (3-D), and most recently, four-dimensional (4-D). These

imaging techniques, while relying mainly on seismic data acquired in the

field, are becoming more and more sophisticated. Computer technology has

advanced so far that it is now possible to incorporate the data obtained

from different types of tests, such as logging, production information,

and gravimetric testing, which can all be combined to create a

'visualization' of the underground formation. Thus geologists and

geophysicists are able to combine all of their sources of data to compile

one clear, complete image of subsurface geology. An example of this is

shown where a geologist uses an interactive computer generated

visualization of 3-D seismic data to explore the subsurface layers.

3-D Seismic Imaging

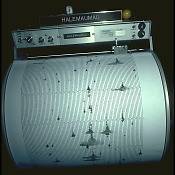

| One of the biggest

breakthroughs in computer-aided exploration was the development of

three-dimensional (3-D) seismic imaging. Three-D imaging utilizes

seismic field data to generate a three dimensional 'picture' of

underground formations and geologic features. This, in essence,

allows the geophysicist and geologist to see a clear picture of the

composition of the Earth's crust in a particular area. This is

tremendously useful in allowing for the exploration of petroleum and

natural gas, as an actual image could be used to estimate the

probability of formations existing in a particular area, and the

characteristics of that potential formation. This technology has

been extremely successful in raising the success rate of exploration

efforts. In fact, using 3-D seismic has been estimated to increase

the likelihood of successful reservoir location by 50 percent. |

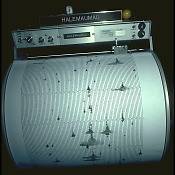

|

|

A

Seismograph |

|

Source: U.S. Geological Survey |

|

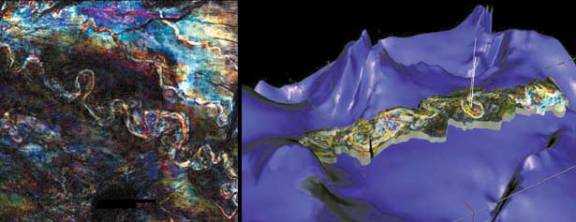

| An

Example of 3-D Seismic Imaging Technology |

|

Source: BP |

Although this technology is

very useful, it is also very costly. Three-D seismic imaging can cost

hundreds of thousands of dollars per square mile. The generation of 3-D

images requires data to be collected from several thousand locations, as

opposed to 2-D imaging, which only requires several hundred data points.

As such, 3-D imaging is a much more involved and prolonged process.

Therefore, it is usually used in conjunction with other exploration

techniques. For example, a geophysicist may use traditional 2-D modeling

and examination of geologic features to determine if there is a

probability of the presence of natural gas. Once these basic techniques

are used, 3-D seismic imaging may be used only in those areas that have a

high probability of containing reservoirs.

|

|

Seismic Imaging in Practice |

|

Source: BP |

In addition to broadly

locating petroleum reservoirs, 3-D seismic imaging allows for the more

accurate placement of wells to be drilled. This increases the productivity

of successful wells, allowing for more petroleum and natural gas to be

extracted from the ground. In fact, 3-D seismic can increase the recovery

rates of productive wells to 40-50 percent, as opposed to 25-30 percent

with traditional 2-D exploration techniques.

In addition to broadly

locating petroleum reservoirs, 3-D seismic imaging allows for the more

accurate placement of wells to be drilled. This increases the productivity

of successful wells, allowing for more petroleum and natural gas to be

extracted from the ground. In fact, 3-D seismic can increase the recovery

rates of productive wells to 40 to 50 percent or greater, as opposed to 25

to 30 percent with traditional 2-D exploration techniques.

Three-D seismic imaging has

become an extremely important tool in the search natural gas. By 1980,

only 100 3-D seismic imaging tests had been performed. However, by the mid

1990s, 200 to 300 3-D seismic surveys were being performed each year. In

1996, in the Gulf of Mexico, one of the largest natural gas-producing

areas in the U.S., nearly 80 percent of wells drilled in the Gulf were

based on 3-D seismic data. In 1993, 75 percent of all onshore exploratory

surveys conducted used 3-D seismic imaging.

2-D Seismic Imaging

Two-dimensional (2-D)

computer-assisted exploration includes generating an image of subsurface

geology much in the same manner as in normal 2-D data interpretation.

However, with the aid of computer technology, it is possible to generate

more detailed maps more quickly than by the traditional method. In

addition, with 2-D CAEX it is possible to use color graphic displays

generated by a computer to highlight geologic features that may not be

apparent using traditional 2-D seismic imaging methods.

While 2-D seismic imaging

is less complicated and less detailed than 3-D imaging, it must be noted

that 3-D imaging techniques were developed prior to 2-D techniques. Thus,

although it does not appear to be the logical progression of techniques,

the simpler 2-D imaging techniques were actually an extension of 3-D

techniques, not the other way around. Because it is simpler, 2-D imaging

is much cheaper, and more easily and quickly performed, than 3-D imaging.

Because of this, 2-D CAEX imaging may be used in areas that are somewhat

likely to contain natural gas deposits, but not likely enough to justify

the full cost and time commitment required by 3-D imaging.

4-D Seismic Imaging

One of the latest

breakthroughs in seismic exploration and the modeling of underground rock

formations has been the introduction of four-dimensional (4-D) seismic

imaging. This type of imaging is an extension of 3-D imaging technology.

However, instead of achieving a simple, static image of the underground,

in 4-D imaging the changes in structures and properties of underground

formations are observed over time. Since the fourth dimension in 4-D

imaging is time, it is also referred to as 4-D 'time lapse' imaging.

|

Geologists and Geophysicists:

Assembling Data |

|

Source: NGSA |

Various seismic readings of

a particular area are taken at different times, and this sequence of data

is fed into a powerful computer. The different images are amalgamated to

create a 'movie' of what is going on under the ground. By studying how

seismic images change over time, geologists can gain a better

understanding of many properties of the rock, including underground fluid

flow, viscosity, temperature and saturation. Although very important in

the exploration process, 4-D seismic images can also be used by petroleum

geologists to evaluate the properties of a reservoir, including how it is

expected to deplete once petroleum extraction has begun. Using 4-D imaging

on a reservoir can increase recovery rates above what can be achieved

using 2-D or 3-D imaging. Where the recovery rates using these two types

of images are 25 to 30 percent and 40 to 50 percent respectively, the use

of 4-D imaging can result in recovery rates of 65 to 70 percent.

Now that we have taken a look

at how natural gas deposits are found, the next step in the natural gas

line is the process of extraction.

Drilling Techniques

Horizontal Drilling

Horizontal drilling starts with a vertical well that turns horizontal

within the reservoir rock in order to expose more open hole to the

oil. These horizontal "legs" can be over a mile long; the longer the

exposure length, the more oil and natural gas is drained and the

faster it can flow. More oil and natural gas can be produced with

fewer wells and less surface disturbance. However, the technology only

can be employed in certain locations.

Multilateral Drilling

Sometimes oil and natural gas reserves are located in separate layers

underground. Multilateral drilling allows producers to branch out from

the main well to tap reserves at different depths. This dramatically

increases production from a single well and reduces the number of

wells drilled on the surface.

Extended Reach Drilling

Extended Reach Drilling allows producers to reach deposits that are

great distances away from the drilling rig. This can help producers

tap oil and natural gas deposits under surface areas where a vertical

well cannot be drilled, such as under developed or environmentally

sensitive areas. Wells can now reach out over 5 miles from the surface

location. Offshore, the use of extended reach drilling allows

producers to reach accumulations far from offshore platforms,

minimizing the number of platforms needed to produce all the oil and

gas. Onshore, dozens of wells can be drilled from a single location,

reducing surface impacts.

Complex Path Drilling

Complex Path Drilling creates well paths with have multiple twists and

turns to try to hit multiple accumulations from a single well

location. Using this technology can be more cost effective and produce

less waste and surface impacts than drilling multiple wells.

|

|

|

|

Source: Duke Energy Gas Transmission Canada |

Natural gas, as it

is used by consumers, is much different from the natural

gas that is brought from underground up to the wellhead.

Although the processing of natural gas is in many

respects less complicated than the processing and

refining of crude oil, it is equally as necessary before

its use by end users.

The natural gas

used by consumers is composed almost entirely of

methane. However, natural gas found at the wellhead,

although still composed primarily of methane, is by no

means as pure. Raw natural gas comes from three types of

wells: oil wells, gas wells, and condensate wells.

Natural gas that comes from oil wells is typically

termed 'associated gas'. This gas can exist separate

from oil in the formation (free gas), or dissolved in

the crude oil (dissolved gas). Natural gas from gas and

condensate wells, in which there is little or no crude

oil, is termed 'nonassociated gas'. Gas wells typically

produce raw natural gas by itself, while condensate

wells produce free natural gas along with a semi-liquid

hydrocarbon condensate. Whatever the source of the

natural gas, once separated from crude oil (if present)

it commonly exists in mixtures with other hydrocarbons;

principally ethane, propane, butane, and pentanes. In

addition, raw natural gas contains water vapor, hydrogen

sulfide (H2S), carbon dioxide, helium,

nitrogen, and other compounds.

Natural gas

processing consists of separating all of the various

hydrocarbons and fluids from the pure natural gas, to

produce what is known as 'pipeline quality' dry natural

gas. Major transportation pipelines usually impose

restrictions on the make-up of the natural gas that is

allowed into the pipeline. That means that before the

natural gas can be transported it must be purified.

While the ethane, propane, butane, and pentanes must be

removed from natural gas, this does not mean that they

are all 'waste products'.

In fact,

associated hydrocarbons, known as 'natural gas liquids'

(NGLs) can be very valuable by-products of natural gas

processing. NGLs include ethane, propane, butane,

iso-butane, and natural gasoline. These NGLs are sold

separately and have a variety of different uses;

including enhancing oil recovery in oil wells, providing

raw materials for oil refineries or petrochemical

plants, and as sources of energy.

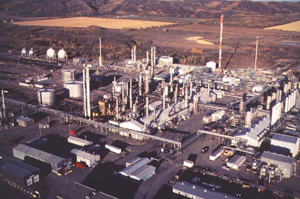

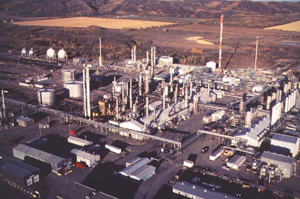

|

|

A Natural Gas Processing Plant |

|

Source: Duke Energy Gas Transmission Canada |

While some of the

needed processing can be accomplished at or near the

wellhead (field processing), the complete processing of

natural gas takes place at a processing plant, usually

located in a natural gas producing region. The extracted

natural gas is transported to these processing plants

through a network of gathering pipelines, which are

small-diameter, low pressure pipes. A complex gathering

system can consist of thousands of miles of pipes,

interconnecting the processing plant to upwards of 100

wells in the area. According to the American Gas

Association's Gas Facts 2000, there was an estimated

36,100 miles of gathering system pipelines in the U.S.

in 1999.

In addition to

processing done at the wellhead and at centralized

processing plants, some final processing is also

sometimes accomplished at 'straddle extraction plants'.

These plants are located on major pipeline systems.

Although the natural gas that arrives at these straddle

extraction plants is already of pipeline quality, in

certain instances there still exist small quantities of

NGLs, which are extracted at the straddle plants.

The actual

practice of processing natural gas to pipeline dry gas

quality levels can be quite complex, but usually

involves four main processes to remove the various

impurities:

- Oil and

Condensate Removal

- Water Removal

- Separation of

Natural Gas Liquids

- Sulfur and

Carbon Dioxide Removal

In addition to the

four processes above, heaters and scrubbers are

installed, usually at or near the wellhead. The

scrubbers serve primarily to remove sand and other

large-particle impurities. The heaters ensure that the

temperature of the gas does not drop too low. With

natural gas that contains even low quantities of water,

natural gas hydrates have a tendency to form when

temperatures drop. These hydrates are solid or

semi-solid compounds, resembling ice like crystals.

Should these hydrates accumulate, they can impede the

passage of natural gas through valves and gathering

systems. To reduce the occurrence of hydrates, small

natural gas-fired heating units are typically installed

along the gathering pipe wherever it is likely that

hydrates may form.

Oil and

Condensate Removal

In order to

process and transport associated dissolved natural gas,

it must be separated from the oil in which it is

dissolved. This separation of natural gas from oil is

most often done using equipment installed at or near the

wellhead.

The actual process

used to separate oil from natural gas, as well as the

equipment that is used, can vary widely. Although dry

pipeline quality natural gas is virtually identical

across different geographic areas, raw natural gas from

different regions may have different compositions and

separation requirements. In many instances, natural gas

is dissolved in oil underground primarily due to the

pressure that the formation is under. When this natural

gas and oil is produced, it is possible that it will

separate on its own, simply due to decreased pressure;

much like opening a can of soda pop allows the release

of dissolved carbon dioxide. In these cases, separation

of oil and gas is relatively easy, and the two

hydrocarbons are sent separate ways for further

processing. The most basic type of separator is known as

a conventional separator. It consists of a simple closed

tank, where the force of gravity serves to separate the

heavier liquids like oil, and the lighter gases, like

natural gas.

|

|

Gas Processing Engineers |

|

Source: ChevronTexaco Corporation |

In certain

instances, however, specialized equipment is necessary

to separate oil and natural gas. An example of this type

of equipment is the Low-Temperature Separator (LTX).

This is most often used for wells producing high

pressure gas along with light crude oil or condensate.

These separators use pressure differentials to cool the

wet natural gas and separate the oil and condensate. Wet

gas enters the separator, being cooled slightly by a

heat exchanger. The gas then travels through a high

pressure liquid 'knockout', which serves to remove any

liquids into a low-temperature separator. The gas then

flows into this low-temperature separator through a

choke mechanism, which expands the gas as it enters the

separator. This rapid expansion of the gas allows for

the lowering of the temperature in the separator. After

liquid removal, the dry gas then travels back through

the heat exchanger and is warmed by the incoming wet

gas. By varying the pressure of the gas in various

sections of the separator, it is possible to vary the

temperature, which causes the oil and some water to be

condensed out of the wet gas stream. This basic

pressure-temperature relationship can work in reverse as

well, to extract gas from a liquid oil stream.

Water Removal

In addition to

separating oil and some condensate from the wet gas

stream, it is necessary to remove most of the associated

water. Most of the liquid, free water associated with

extracted natural gas is removed by simple separation

methods at or near the wellhead. However, the removal of

the water vapor that exists in solution in natural gas

requires a more complex treatment. This treatment

consists of 'dehydrating' the natural gas, which usually

involves one of two processes: either absorption, or

adsorption.

Absorption occurs

when the water vapor is taken out by a dehydrating

agent. Adsorption occurs when the water vapor is

condensed and collected on the surface.

Glycol

Dehydration

An example of

absorption dehydration is known as Glycol Dehydration.

In this process, a liquid desiccant dehydrator serves to

absorb water vapor from the gas stream. Glycol, the

principal agent in this process, has a chemical affinity

for water. This means that, when in contact with a

stream of natural gas that contains water, glycol will

serve to 'steal' the water out of the gas stream.

Essentially, glycol dehydration involves using a glycol

solution, usually either diethylene glycol (DEG) or

triethylene glycol (TEG), which is brought into contact

with the wet gas stream in what is called the

'contactor'. The glycol solution will absorb water from

the wet gas. Once absorbed, the glycol particles become

heavier and sink to the bottom of the contactor where

they are removed. The natural gas, having been stripped

of most of its water content, is then transported out of

the dehydrator. The glycol solution, bearing all of the

water stripped from the natural gas, is put through a

specialized boiler designed to vaporize only the water

out of the solution. While water has a boiling point of

212 degrees Fahrenheit, glycol does not boil until 400

degrees Fahrenheit. This boiling point differential

makes it relatively easy to remove water from the glycol

solution, allowing it be reused in the dehydration

process.

A new innovation

in this process has been the addition of flash tank

separator-condensers. As well as absorbing water from

the wet gas stream, the glycol solution occasionally

carries with it small amounts of methane and other

compounds found in the wet gas. In the past, this

methane was simply vented out of the boiler. In addition

to losing a portion of the natural gas that was

extracted, this venting contributes to air pollution and

the greenhouse effect. In order to decrease the amount

of methane and other compounds that are lost, flash tank

separator-condensers work to remove these compounds

before the glycol solution reaches the boiler.

Essentially, a flash tank separator consists of a device

that reduces the pressure of the glycol solution stream,

allowing the methane and other hydrocarbons to vaporize

('flash'). The glycol solution then travels to the

boiler, which may also be fitted with air or water

cooled condensers, which serve to capture any remaining

organic compounds that may remain in the glycol

solution. In practice, according to the Department of

Energy's Office of Fossil Energy, these systems have

been shown to recover 90 to 99 percent of methane that

would otherwise be flared into the atmosphere.

Solid-Desiccant

Dehydration

Solid-desiccant

dehydration is the primary form of dehydrating natural

gas using adsorption, and usually consists of two or

more adsorption towers, which are filled with a solid

desiccant. Typical desiccants include activated alumina

or a granular silica gel material. Wet natural gas is

passed through these towers, from top to bottom. As the

wet gas passes around the particles of desiccant

material, water is retained on the surface of these

desiccant particles. Passing through the entire

desiccant bed, almost all of the water is adsorbed onto

the desiccant material, leaving the dry gas to exit the

bottom of the tower.

|

|

Absorption Towers |

|

Source: Duke Energy Gas Transmission Canada |

Solid-desiccant

dehydrators are typically more effective than glycol

dehydrators, and are usually installed as a type of

straddle system along natural gas pipelines. These types

of dehydration systems are best suited for large volumes

of gas under very high pressure, and are thus usually

located on a pipeline downstream of a compressor

station. Two or more towers are required due to the fact

that after a certain period of use, the desiccant in a

particular tower becomes saturated with water. To

'regenerate' the desiccant, a high-temperature heater is

used to heat gas to a very high temperature. Passing

this heated gas through a saturated desiccant bed

vaporizes the water in the desiccant tower, leaving it

dry and allowing for further natural gas dehydration.

|

Separation of Natural Gas Liquids

Natural

gas coming directly from a well contains many

natural gas liquids that are commonly removed.

In most instances, natural gas liquids (NGLs)

have a higher value as separate products, and it

is thus economical to remove them from the gas

stream. The removal of natural gas liquids

usually takes place in a relatively centralized

processing plant, and uses techniques similar to

those used to dehydrate natural gas.

There are

two basic steps to the treatment of natural gas

liquids in the natural gas stream. First, the

liquids must be extracted from the natural gas.

Second, these natural gas liquids must be

separated themselves, down to their base

components. |

|

|

Gas Processing Plant with Absorption

Towers |

|

Source: Duke Energy Gas Transmission

Canada |

|

NGL Extraction

There are two

principle techniques for removing NGLs from the natural

gas stream: the absorption method and the cryogenic

expander process. According to the Gas Processors

Association, these two processes account for around 90

percent of total natural gas liquids production.

The Absorption

Method

|

|

Pipes and Absorption Towers |

|

Source: Duke Energy Gas Transmission Canada |

The absorption

method of NGL extraction is very similar to using

absorption for dehydration. The main difference is that,

in NGL absorption, an absorbing oil is used as opposed

to glycol. This absorbing oil has an 'affinity' for NGLs

in much the same manner as glycol has an affinity for

water. Before the oil has picked up any NGLs, it is

termed 'lean' absorption oil. As the natural gas is

passed through an absorption tower, it is brought into

contact with the absorption oil which soaks up a high

proportion of the NGLs. The 'rich' absorption oil, now

containing NGLs, exits the absorption tower through the

bottom. It is now a mixture of absorption oil, propane,

butanes, pentanes, and other heavier hydrocarbons. The

rich oil is fed into lean oil stills, where the mixture

is heated to a temperature above the boiling point of

the NGLs, but below that of the oil. This process allows

for the recovery of around 75 percent of butanes, and 85

- 90 percent of pentanes and heavier molecules from the

natural gas stream.

The basic

absorption process above can be modified to improve its

effectiveness, or to target the extraction of specific

NGLs. In the refrigerated oil absorption method, where

the lean oil is cooled through refrigeration, propane

recovery can be upwards of 90 percent, and around 40

percent of ethane can be extracted from the natural gas

stream. Extraction of the other, heavier NGLs can be

close to 100 percent using this process.

The Cryogenic

Expansion Process

Cryogenic

processes are also used to extract NGLs from natural

gas. While absorption methods can extract almost all of

the heavier NGLs, the lighter hydrocarbons, such as

ethane, are often more difficult to recover from the

natural gas stream. In certain instances, it is economic

to simply leave the lighter NGLs in the natural gas

stream. However, if it is economic to extract ethane and

other lighter hydrocarbons, cryogenic processes are

required for high recovery rates. Essentially, cryogenic

processes consist of dropping the temperature of the gas

stream to around -120 degrees Fahrenheit.

There are a number

of different ways of chilling the gas to these

temperatures, but one of the most effective is known as

the turbo expander process. In this process, external

refrigerants are used to cool the natural gas stream.

Then, an expansion turbine is used to rapidly expand the

chilled gases, which causes the temperature to drop

significantly. This rapid temperature drop condenses

ethane and other hydrocarbons in the gas stream, while

maintaining methane in gaseous form. This process allows

for the recovery of about 90 to 95 percent of the ethane

originally in the gas stream. In addition, the expansion

turbine is able to convert some of the energy released

when the natural gas stream is expanded into

recompressing the gaseous methane effluent, thus saving

energy costs associated with extracting ethane.

The extraction of

NGLs from the natural gas stream produces both cleaner,

purer natural gas, as well as the valuable hydrocarbons

that are the NGLs themselves.

Natural Gas

Liquid Fractionation

Once NGLs have

been removed from the natural gas stream, they must be

broken down into their base components to be useful.

That is, the mixed stream of different NGLs must be

separated out. The process used to accomplish this task

is called fractionation. Fractionation works based on

the different boiling points of the different

hydrocarbons in the NGL stream. Essentially,

fractionation occurs in stages consisting of the boiling

off of hydrocarbons one by one. The name of a particular

fractionator gives an idea as to its purpose, as it is

conventionally named for the hydrocarbon that is boiled

off. The entire fractionation process is broken down

into steps, starting with the removal of the lighter

NGLs from the stream. The particular fractionators are

used in the following order:

- Deethanizer

- this step separates the ethane from the NGL

stream.

- Depropanizer

- the next step separates the propane.

- Debutanizer

- this step boils off the butanes, leaving the

pentanes and heavier hydrocarbons in the NGL stream.

- Butane

Splitter or Deisobutanizer - this step separates

the iso and normal butanes.

By proceeding from

the lightest hydrocarbons to the heaviest, it is

possible to separate the different NGLs reasonably

easily.

Sulfur and

Carbon Dioxide Removal

In addition to

water, oil, and NGL removal, one of the most important

parts of gas processing involves the removal of sulfur

and carbon dioxide. Natural gas from some wells contains

significant amounts of sulfur and carbon dioxide. This

natural gas, because of the rotten smell provided by its

sulfur content, is commonly called 'sour gas'. Sour gas

is undesirable because the sulfur compounds it contains

can be extremely harmful, even lethal, to breathe. Sour

gas can also be extremely corrosive. In addition, the

sulfur that exists in the natural gas stream can be

extracted and marketed on its own. In fact, according to

the USGS, U.S. sulfur production from gas processing

plants accounts for about 15 percent of the total U.S.

production of sulfur.

|

|

Gas Sweetening Plant |

|

Source: Duke Energy Gas Transmission Canada |

Sulfur exists in

natural gas as hydrogen sulfide (H2S), and

the gas is usually considered sour if the hydrogen

sulfide content exceeds 5.7 milligrams of H2S

per cubic meter of natural gas. The process for removing

hydrogen sulfide from sour gas is commonly referred to

as 'sweetening' the gas.

The primary

process for sweetening sour natural gas is quite similar

to the processes of glycol dehydration and NGL

absorption. In this case, however, amine solutions are

used to remove the hydrogen sulfide. This process is

known simply as the 'amine process', or alternatively as

the Girdler process, and is used in 95 percent of U.S.

gas sweetening operations. The sour gas is run through a

tower, which contains the amine solution. This solution

has an affinity for sulfur, and absorbs it much like

glycol absorbing water. There are two principle amine

solutions used, monoethanolamine (MEA) and

diethanolamine (DEA). Either of these compounds, in

liquid form, will absorb sulfur compounds from natural

gas as it passes through. The effluent gas is virtually

free of sulfur compounds, and thus loses its sour gas

status. Like the process for NGL extraction and glycol

dehydration, the amine solution used can be regenerated

(that is, the absorbed sulfur is removed), allowing it

to be reused to treat more sour gas.

Although most sour

gas sweetening involves the amine absorption process, it

is also possible to use solid desiccants like iron

sponges to remove the sulfide and carbon dioxide.

Sulfur can be sold

and used if reduced to its elemental form. Elemental

sulfur is a bright yellow powder like material, and can

often be seen in large piles near gas treatment plants,

as is shown. In order to recover elemental sulfur from

the gas processing plant, the sulfur containing

discharge from a gas sweetening process must be further

treated. The process used to recover sulfur is known as

the Claus process, and involves using thermal and

catalytic reactions to extract the elemental sulfur from

the hydrogen sulfide solution.

|

|

Elemental Sulfur Production in a Gas Treatment

Plant |

|

Source: Duke Energy Gas Transmission Canada |

In all, the Claus

process is usually able to recover 97 percent of the

sulfur that has been removed from the natural gas

stream. Since it is such a polluting and harmful

substance, further filtering, incineration, and 'tail

gas' clean up efforts ensure that well over 98 percent

of the sulfur is recovered.

Gas processing is

an instrumental piece of the natural gas value chain. It

is instrumental in ensuring that the natural gas

intended for use is as clean and pure as possible,

making it the clean burning and environmentally sound

energy choice. Once the natural gas has been fully

processed, and is ready to be consumed, it must be

transported from those areas that produce natural gas,

to those areas that require it.

|

|

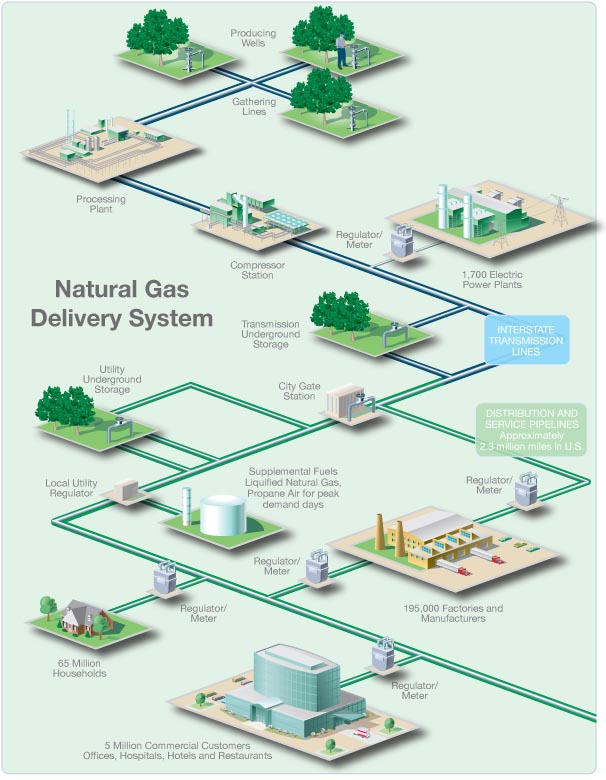

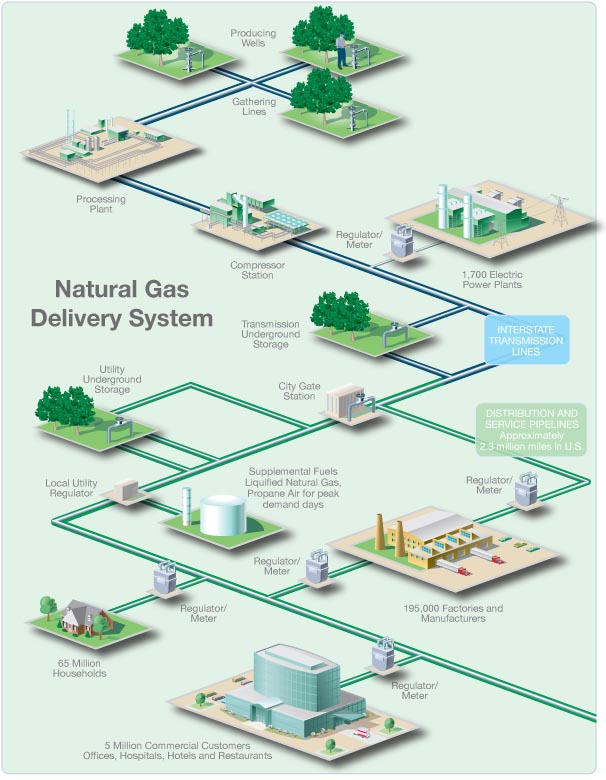

Natural gas is moved

by pipelines from the producing fields to consumers. Since natural gas demand is

greater in the winter, gas is stored along the way in large underground storage

systems, such as old oil and gas wells or caverns formed in old salt beds. The

gas remains there until it is added back into the pipeline when people begin to

use more gas, such as in the winter to heat homes. When chilled to very cold

temperatures, approximately -260 degrees Fahrenheit, natural gas changes into a

liquid and can be stored in this form. Liquefied natural gas (LNG) can be loaded

onto tankers (large ships with several domed tanks) and moved across the ocean

to deliver gas to other countries. Once in this form, it takes up only 1/600th

of the space that it would in its gaseous state. When this LNG is received in

the United States, it can be shipped by truck to be held in large chilled tanks

close to users or turned back into gas to add to pipelines.

Natural gas -

proved reserves

Credit:BP, Energy

Information Administration, U.S. Department of Energy, CIA, American Gas

Association, Association of Oil Pipe Lines

|